Underground

Service Company provides

utility location services, independent line

testing, leak location surveys, and turn-key repairs. We

serve energy companies, water districts, environmental

engineers, and pipeline contractors.

We have included limitations,

advantages, and requirements for each survey method and the parameters required for a successful on

site test. This information is intended to be used as

a guide. For a site-specific proposal, please

contact us.

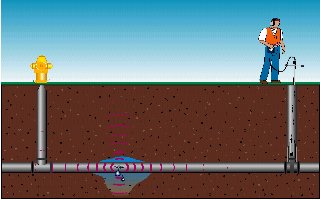

Leak Survey - Acoustic Testing

Impact noise created

by a leak on an underground pipeline travels along the pipe

wall and through the fluid column inside the pipe.

Significantly sized leaks also create a vibration that

travels outward through the soil and to the ground surface.

This leak noise can be

identified with the help of an

acoustic listening system at available contact points to

pipeline appurtenances and ground surface over the top of

pipe. The distance to which the noise travels from the leak

outward along the pipeline and through the soil changes with

different factors, the most important being the leak rate,

the pipe size and type, and the dynamics of the surrounding

soil.

Impact noise created

by a leak on an underground pipeline travels along the pipe

wall and through the fluid column inside the pipe.

Significantly sized leaks also create a vibration that

travels outward through the soil and to the ground surface.

This leak noise can be

identified with the help of an

acoustic listening system at available contact points to

pipeline appurtenances and ground surface over the top of

pipe. The distance to which the noise travels from the leak

outward along the pipeline and through the soil changes with

different factors, the most important being the leak rate,

the pipe size and type, and the dynamics of the surrounding

soil.

Applications:

The acoustic method can be beneficial on larger leaks (1/2

gallon per minute plus) because it is a relatively fast

procedure that usually does not require the set up that a

tracer gas survey does.

The following table shows the

amount of leakage in terms of gallons per minute that is

able to be detected by the equipment on the given pipeline

from a distance of 200 feet from contact points in ideal

conditions. This table is intended as a guideline, figures

used are approximate, and results can vary with site

conditions.

|

Dia.

|

Iron

|

PVC

|

CLMC

|

Steel

|

A/C

|

|

2"

|

1/2 gpm

|

1

gpm

|

n/a

|

< 1/2 gpm

|

n/a

|

|

6"

|

3/4 gpm

|

1.5 gpm

|

1

gpm

|

1/2 gpm

|

1

gpm

|

|

18"

|

1.5 gpm

|

2.5 gpm

|

2

gpm

|

1

gpm

|

2.5 gpm

|

|

36"

|

2

gpm

|

3.5 gpm

|

2.5 gpm

|

1.5 gpm

|

n/a |

(200 psi test pressure)

If the rate of the leak is

unknown, then a pressure test should be performed if able to

aid in calculation of the rate of the leak. If a pressure

test cannot be preformed, a cursory acoustic survey should

be administered.

-

Provide all known

information on the site conditions to Underground

Service Company.

-

Ensure that contact points

are accessible.

-

Any valves or appurtenances

that are known to be faulty should be repaired prior to

the test if possible.

-

If able, tests should be

scheduled at a time when any demand, usage, pumping, and

ambient noise is at its lowest levels.

-

The client is responsible

for any required notifications.

Leak Survey - Tracer Gas Test

A mixture of 96%

helium and 4% hydrogen is combined with compressed air as it

is introduced into the piping test segment. The gas is

purged through the system allowing a full column of gas to

be present within the pipeline. A varying soak time is

required to allow the gas to escape through the leak to

permeate the soil and reach the surface where a gas analyzer

is used by an operator to record concentrations. Some

conditions may required that 1/2 inch diameter holes be

drilled through the surface area to expedite the process

such as cases of thick concrete or asphalt surfaces acting

as a "cap" to the permeating tracer gas. The operator is

able to observe readings as slight as 25 parts per million.

Applications: The tracer gas method

allows for the identification of leaks that the acoustic

method cannot. It doesn't particularly matter what type

or size of pipe is leaking. Ambient noise conditions on

site do not affect the test. The important factor for

success is enabling the tracer gas to be properly purged

through the test segment to the leak. The line must be

able to be isolated for proper purging. The tracer

method is ideal for:

-

Any type or size of pipe.

-

Smaller leaks that cannot

be found using the acoustic method.

-

Beneficial in deep

elevation and transmission lines.

|

Site Preparation:

Ideally, a test segment would include a truly isolated

system with an induction point for the gas at one end

and a venting point available for proper purging at the

opposite end. If this condition does not exist,

additional time on site may be required for purging or

added procedures. If the client is able, it is

recommended that the test segment be drained prior to

testing.

Underground Service Company provides all

piping adaptors needed for tracer induction up to 4"

I.P.T.